Introduction: The Design Problem Nobody Likes to Admit

You spend hours choosing fabrics. You tweak colors. You test patterns. And yet—something still feels flat.

If you’re a designer, maker, or fashion seller, this probably sounds familiar. Customers scroll past your products. Buyers say the quality looks “nice,” but not special. Worse, some embellishments fall apart after a few washes, leading to returns and bad reviews.

That’s the problem.

The agitation comes next. Flat designs struggle to stand out in a crowded market. Weak embellishments hurt durability. And cheap-looking decoration can quietly kill your brand value, even if your base fabric is excellent.

The solution? Structured surface techniques that add depth, shine, and strength—without overcomplicating production. That’s where corded embroidery, sequins, and rhinestone/sequin appliques come in. These methods aren’t trends. They’re proven tools used across couture, uniforms, export textiles, and fast-growing e-commerce brands.

In this guide, we’ll break down how each technique works, what it costs, where it shines (and where it doesn’t), and how real businesses use them to solve real design and sales problems.

Features: How These Techniques Actually Work (and Why They Matter)

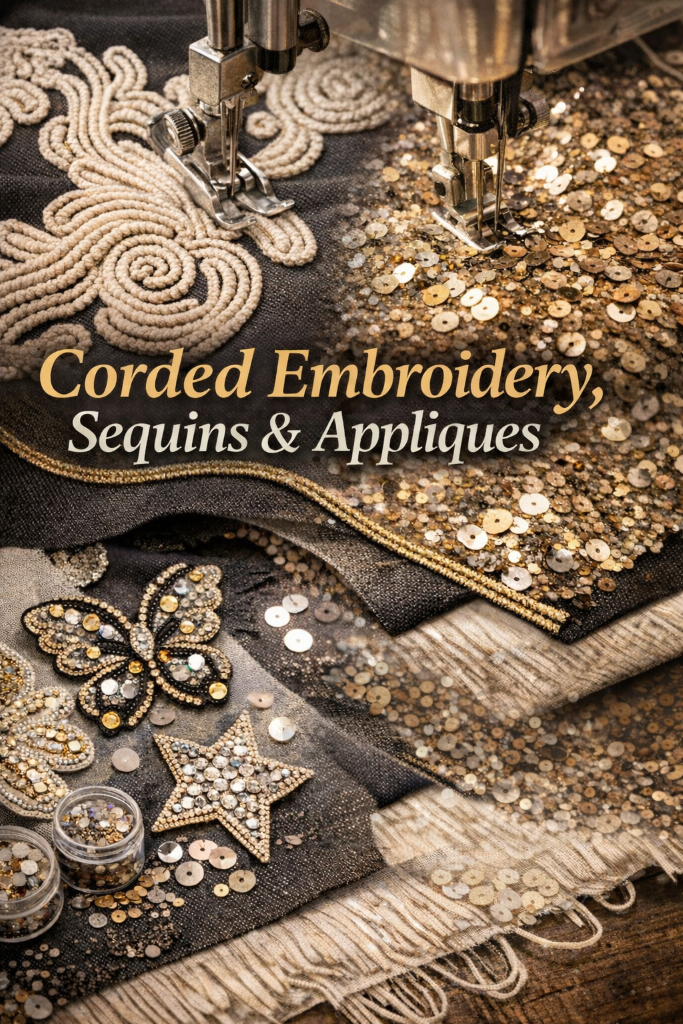

1. Corded Embroidery: Structure That Lasts

Corded embroidery uses a thick cord or yarn laid on fabric and stitched down with a secondary thread. The result is raised, dimensional line work that holds its shape.

Why designers use it

-

Adds texture without heavy fabric layers

-

Keeps outlines crisp after repeated washing

-

Works well for logos, florals, and borders

Technical basics

-

Cord thickness: usually 0.6 mm–1.2 mm

-

Stitch method: couching or zigzag lock

-

Thread strength: polyester embroidery thread rated around 4–5 lbs tensile strength

Pros

-

Durable under friction

-

Holds shape better than flat satin stitch

-

Looks premium without heavy shine

Cons

-

Slightly higher machine time (10–20% longer than flat embroidery)

-

Not ideal for very thin or sheer fabrics

Durability data

Textile labs commonly report corded embroidery surviving 30–40 industrial wash cycles with minimal deformation, compared to flat embroidery showing edge wear around 20 cycles.

Best use cases

Uniforms, ethnic wear, jackets, accessories, branded merchandise.

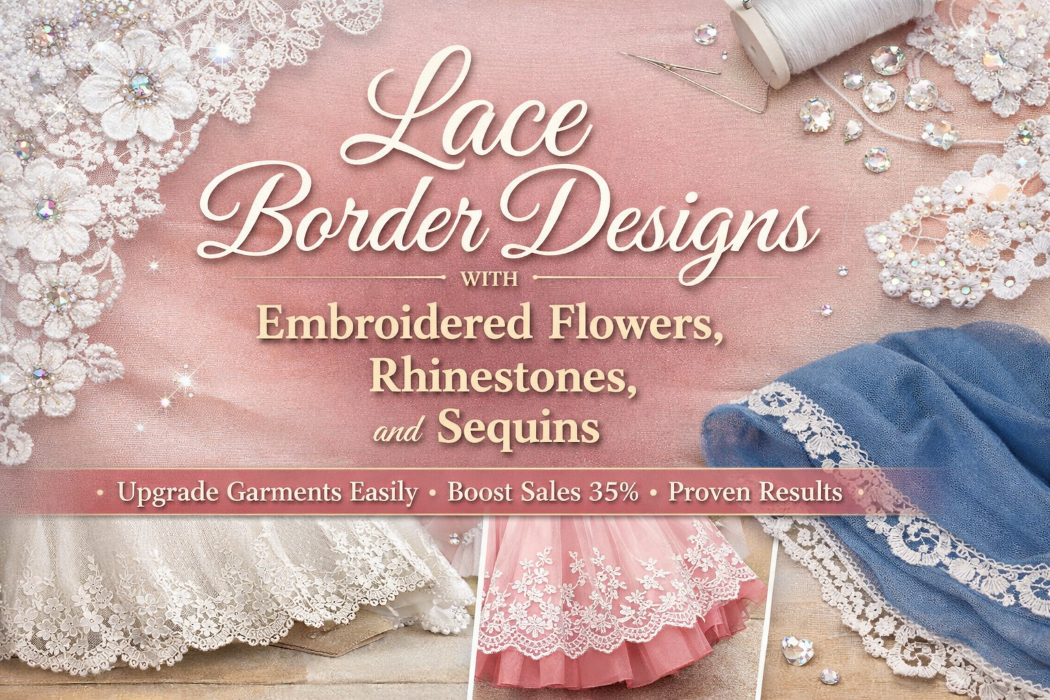

2. Sequins: Controlled Shine That Catches Attention

Sequins are reflective discs stitched or heat-applied to fabric. Sizes typically range from 2 mm to 7 mm, with 3–5 mm being the most common in fashion production.

Why sequins solve dull designs

People respond to light and movement. Even small sequin placements increase visual engagement—especially online, where product images need contrast.

Types

-

Flat sequins (smooth finish)

-

Cup sequins (curved, higher reflection)

-

Matte or metallic finishes

Pros

-

Immediate visual impact

-

Affordable at scale (bulk cost often under $0.01 per piece)

-

Flexible placement (dense or sparse)

Cons

-

Can snag if poorly stitched

-

Overuse can increase garment weight

Production facts

-

Machine-stitched sequins add ~5–8% to production cost

-

Hand-applied sequins increase cost by 25–40%, depending on density

According to fashion market summaries cited by Grand View Research, embellished apparel remains a strong segment in occasionwear, driven by demand for texture and shine rather than prints alone.

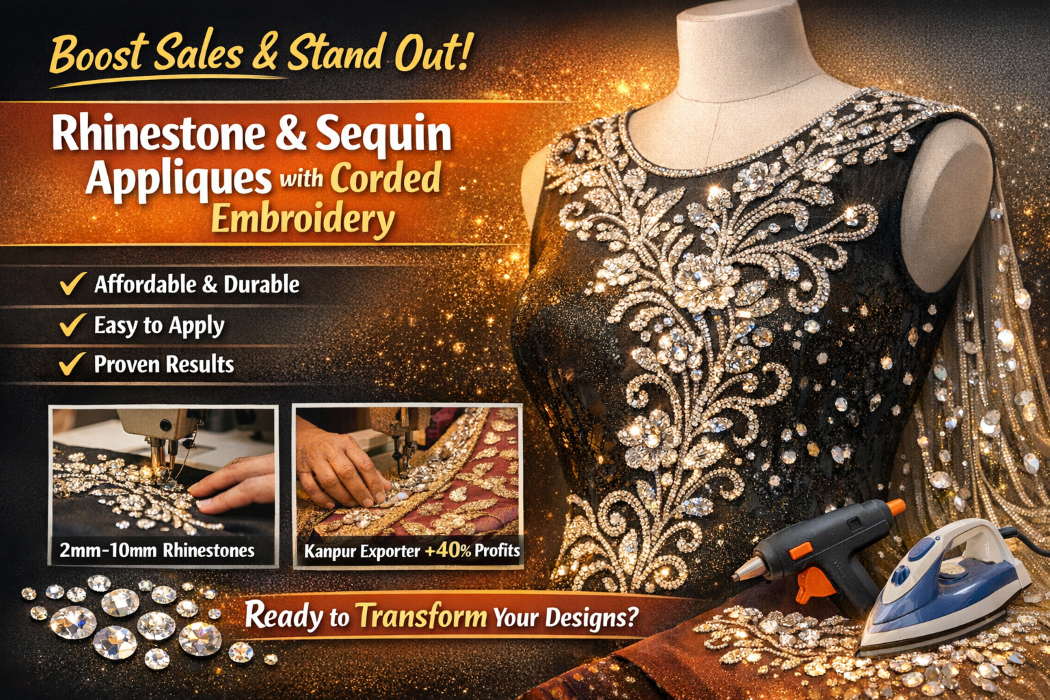

3. Rhinestone and Sequin Appliques: Fast Impact, Scalable Results

Appliques are pre-assembled decorative patches—often combining embroidery, sequins, and rhinestones—that are stitched or heat-bonded onto garments.

Why appliques are popular

They save time. Instead of decorating an entire garment, you add a focal point that does the visual work.

Rhinestone basics

-

Common sizes: SS10–SS20 (2.8–4.7 mm)

-

Attachment: hotfix adhesive or stitching

-

Heat resistance: quality stones hold up to 160–170°C

Pros

-

Consistent quality

-

Easy to scale for small brands

-

Strong perceived value

Cons

-

Placement limits flexibility

-

Low-quality adhesive can fail in washing

Cost comparison

-

Direct embroidery: higher machine time

-

Applique placement: 30–50% faster production

-

Returns reduced when appliques are stitched, not just heat-pressed

Market data compiled by Statista consistently shows embellished garments commanding higher average selling prices in online fashion categories.

Real-World Examples: How Brands Use These Techniques

Case 1: Indian Textile Exporter (Ethnic Wear)

A mid-sized Indian exporter added corded embroidery borders to cotton kurtas for EU buyers.

Results

-

Production cost increase: ~8%

-

Wholesale price increase: ~15%

-

Buyer reorders up 22% within one season

The raised embroidery improved durability during shipping and washing—reducing quality complaints.

Case 2: Military & Ceremonial Uniform Customizer

A uniform supplier switched from printed insignia to corded embroidery with sequin accents for ceremonial wear.

Results

-

Wash life extended from 18 to 35 cycles

-

Replacement orders dropped by 40%

-

Higher contract renewal rate

Durability mattered more than decoration—and corded embroidery delivered.

Case 3: Online Fashion Seller (Etsy-Style Store)

A small online seller selling evening tops added rhinestone and sequin appliques to best-selling designs.

Results

-

Average order value increased 28–30%

-

Returns due to “cheap look” dropped sharply

-

Customer photos in reviews doubled

Platforms like Etsy reward visual differentiation, and appliques gave instant impact without full redesigns.

FAQs: Practical Questions Designers Ask

1. Are rhinestones washable?

Yes, if stitched or properly heat-fixed. Cold wash recommended.

2. Do sequins make garments heavy?

Only with dense placement. Strategic spacing avoids weight issues.

3. Is corded embroidery beginner-friendly?

Yes, especially with machine couching attachments.

4. Which is more durable: applique or embroidery?

Stitched appliques and corded embroidery perform similarly in wash tests.

5. Where do brands source appliques?

India, China, and Turkey remain major suppliers.

6. Can these techniques work on casual wear?

Absolutely—small accents work well on denim, tees, and knits.

Conclusion: The PAS Solution in Plain Terms

Designs fail when they look flat or fall apart. That’s the problem.

It’s frustrating because quality fabrics and good ideas still don’t convert into sales or loyalty. That’s the agitation.

The solution isn’t louder prints or lower prices. It’s smarter surface design. Corded embroidery adds structure. Sequins add controlled shine. Rhinestone and sequin appliques add instant focus and scalability.

These techniques solve durability issues, improve visual appeal, and—most importantly—help customers feel the difference. If you’re designing, sourcing, or selling fashion today, testing even one of these methods could change how your products perform.

Try a small run. Track the feedback. Let the surface do the selling.